Israel can help states like Haryana and Punjab in managing waste, packing, cold storage, dairy processing and recycling sewerage water for use in agriculture

|

Israel plans to set up more centres of excellence in Haryana on the pattern of the one in Gharonda. Similar centres will be established in Punjab, Maharashtra, Karnataka, Gujarat and Tamil Nadu |

Israel has emerged as a leader in various fields, especially water management and renewable energy, science and technology, agriculture and dairy. At Agritech Israel 2012, organised in Tel Aviv from May 15 to 17, Israel showcased some of its latest technologies and farming machinery and dairy practices. Representatives from industry and agriculture, government officials and investors came together on one platform and discussed problems and issues relating, among others, to dairy and agriculture.

Haryana has taken keen interest in picking up the best available farming and dairy practices from Israel. The impact of adoption of Israeli farm technology has started yielding results. The Indo-Israeli centre of excellence for vegetables at Gharonda in Haryana’s Karnal district has been able to match the productivity levels of Israel.

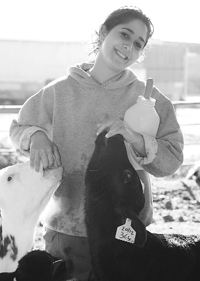

Newborn calves are fed with colostrums, a milk-like substance that strengthens their immune system

“The centre for excellence achieved yields of 302 MT per hectare in tomato, 211 MT in capsicum and 151 MT in cucumber which is on a par with Israel”, according to Haryana Agriculture Minister Paramveer Singh, who was in Tel Aviv for the “20th anniversary of Israel-India diplomatic relations.

As many as 75 varieties of tomato, 14 hybrids of capsicum in seven colours and five hybrids of cucumber have been tested by 100-odd farmers who adopted protected cultivation. Enthused by the phenomenal success of the project, more farmers adopted the new technologies. As a result, 2.20 lakh sq mt area was brought under protected cultivation.

Isreal’s Holstein Friesian cows are among the best. They are fed on dry fodder and never exposed to direct sunlight as heat stress reduces milk yield

The Haryana government plans to start polyhouse cultivation in 5,000 hectare area in the nextfive years. Fourteen frontline demonstrationcentres are being established in various districts on the pattern of the Gharonda centre. The state also plans to establish an international horticulture market on 200 hectare area with an investment of Rs 1,500 crore at Ganaur. Fifteen cold chain facilities have already been setup, 15 collecting centres and an equal number of commodity hubs are in the pipeline.

Haryana now looks forward to collaboration in germ-plasma exchange, bumble bees, nursery management and post-harvest management, especially of fruits and vegetables. The state has a lot to learn from Israel, especially in agriculture development of arid zones for which technology developed by Israel will be useful, adds the minister.

Israeli technology will also help in managing waste, packing, cold storage, dairy processing and recycling sewerage water for use in agriculture, says Vani Rao, a Councillor of the Indian embassy in Israel.

Israeli Minister of Agriculture and Rural Development Orit Noked stressed the need for more collaboration in the fields of food security, water management, renewable energy and environment.

Haryana leads in Indo-Israeli collaborations. Out of the total geographical area of 44.21 lakh hectares in Haryana, 38.09 lakh hectare area is cultivated witha crop intensity of 180 per cent. The area under horticulture is 6.40 per cent of the total cropped land. The share of agriculture and allied activities in the state GDP has risen to 16.3 per cent in 2011-2012.

Excels in milk management

In spite of emerging as the largest milk producer in the world, India faces the problem of low productivity in dairy. On an average, a cow yields 1,300 litres a year. In Israel a cow’s annual yield is 13,000 litres. “Israel also produces high quality milk with a minimum amount of bacteria in it,” says Ronen Koll, Area manager, India and South East Asia, Afimilk.

“We have built sheds where more than 1,000 cows are accommodated. These are designed in such a way that the roof can be opened and closed to adjust to the temperature. The automatic farm has got exhaust fans, drinking water and fodder and it needs merely 12 persons to handle 1,000 cows”, explains Koll. India’s dairy sector faces the challenges of contamination, absence of a cool chain, a high bacteria count and heat stress on cows. Technologies developed byIsrael offer solutions.

According to Israeli experts, the Indian practice of milking animals by hand causes contamination. Mechanised processes to completely avoid a human touch are available. Air exposure while milking is reduced and milk directly flows into cooling containers at 4 degree Celsius. In Israel the bacteria count per mm is 10,000 whereas in India it is as high as 2 lakh per mm.

Heat stress hits milk yield. “We have overcome the problem by providing big ventilators in farms with open/close roofs. Cows are never exposed to direct sun light as they feel heat stress at 25 degrees Celsius and the temperature is maintained below that level. About 60 years ago, local breeds were crossed with European but today we have our world-class Israel Holstein Friesian breeds”, says Ronnen Koll.

Dairy software from Afimilk

A global leader in making advanced computerised systems for dairy farms and herd management, Afimilk was the first to introduce pedometers to monitor cows, dairy farm management software and an online milk analyser.“The pedometer is attached on the feet of each cow to see the heat which is normally at 60 steps and when it increases to 300-400 steps, we come to know that the cow is ready for insemination and the computer reads everything”, he adds.

Newborn calves are separated immediately and are fed with colostrums, a milk-like substance that jump-starts a newborn’s immune system. Milk is tested once a month, every cow has a milk tag, an ear tag and a number for registration. Cows are fed twice a day with fodder comprising silage made of wheat and corn (only dry fodder, calculated in kg) in the 60:40 proportion. No wet fodder is used and there are three milking sessions a day after every eight hours.

A farmer gets 55 cents per litre and even the dry manure cows lay is scrapped by machines and taken to produce bio-mass energy of 4 MW everyday. Feet and mouth diseases are negligible due to vaccination and only one per cent suffer from mitosis. Cooling (mix of fogging andstrong winds) is done by fans at the stands by locking the cows.

Afimilk operating in the cooperative sector on the pattern of Amul is replicating the technology for the first time in India by setting up the first “demo farm” in Gandhinagar in Gujarat which would start functioning in 10 months. There are 300 cooperatives farms of kibutzs (large community groups) and 800 family farms in Israel and the entire demand of milk and milk products is met locally.

Collagen made from tobacco

Prof. Oded Shoseyov of Robert H. Smith faculty of Agriculture, Food and Environment, Hebrew University of Jerusalem (Israel), has produced a replica of human collagen from green tobacco plants, an achievement with tremendous commercial implications for its use in a variety of human medical procedures.

Collagen is a type of protein, fibrous in nature and is an essential component for hundreds of medical products used in orthopedics, diabetes, cardiology, wound healing and many other diseases as human skin contains 70 per cent collagen.

Collagen-based products are used for wound care, surgical meshes, vascular grafts, hem ostasis, drug delivery solutions and corneal shields.

Collagen is usually produced from animalslike cows and pigs as well as human cadavers but these materials are prone to harbour human pathogens such as viruses and prions (mad cow disease). The human cadaver on the other hand is scarce and also raises serious ethical issues.

View Source

By Bhanu P. Lohumi

The writer, a Senior Staff Correspondent of The Tribune, visited Israel from May 12 to 19 to participate in “Agritech Israel 2012”.

Israeli New Shekel Exchange Rate

Israeli New Shekel Exchange Rate